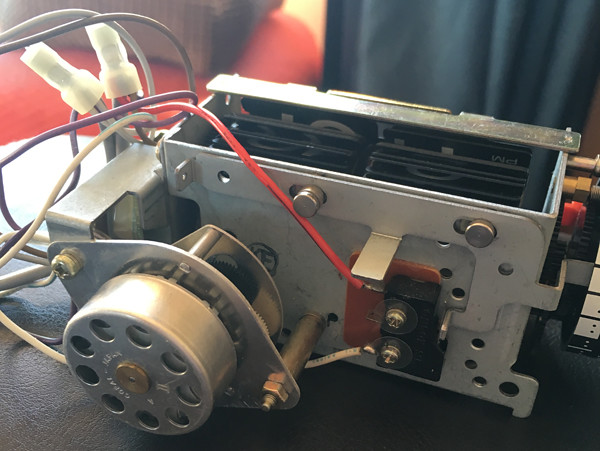

I just picked up a GE 7-4305F flip clock pretty cheap. It was advertised as "working" but it wasn't exactly working well. When I got it the bulb was very dim so I replaced it, and all the switch contacts and volume knob needed a good cleaning. The motor was barely turning so I took the metal cover off of the back and noticed it was a Copal II. I dipped the rotor part in a shot glass full of 99% rubbing alcohol and shook it around. When I lifted it out the alcohol was full of small brown particles. I spun it out and dried the motor with compressed air and tried it again. The motor ran perfectly and completely silent for a while, then started to get noisy and slow down a little. I cleaned it again until barely any dirt came out of it and put it back together.

Overnight the clock lost almost 2 minutes and began to get noisy again. I was going to try spraying lubricant into the rotor part and working it in, without getting any into the gears. Then remove the excess by laying it on paper towels and spraying the motor with air. I have some 3-in-1 professional silicone lubricant in a spray can. It's light and penetrating and dries quickly. It's also safe on plastic, vinyl, and rubber. Would this be suitable to lubricate the motor? Also, should I spray some into the gearbox? It's riveted onto the motor so I can't take the cover off to clean it out. Normally vinyl gears don't need lubrication but I wasn't sure. What about the main metal gear that connects to the clock mechanism? Should that be lubricated?

Overnight the clock lost almost 2 minutes and began to get noisy again. I was going to try spraying lubricant into the rotor part and working it in, without getting any into the gears. Then remove the excess by laying it on paper towels and spraying the motor with air. I have some 3-in-1 professional silicone lubricant in a spray can. It's light and penetrating and dries quickly. It's also safe on plastic, vinyl, and rubber. Would this be suitable to lubricate the motor? Also, should I spray some into the gearbox? It's riveted onto the motor so I can't take the cover off to clean it out. Normally vinyl gears don't need lubrication but I wasn't sure. What about the main metal gear that connects to the clock mechanism? Should that be lubricated?

:

:

: replace the bearings. See this post:

: replace the bearings. See this post:

Comment